What’s New

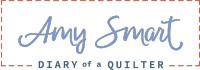

- 25 Favorite Charm Square Quilts & Projects

- Machine Quilting Tips + Using a "Cheater Quilt" for Practice

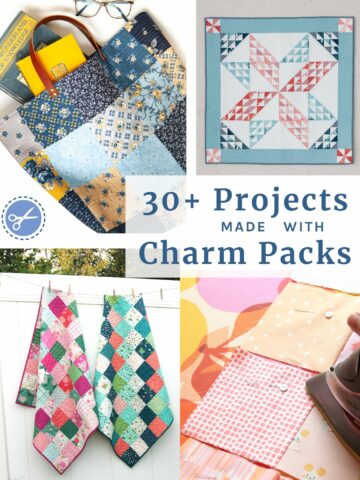

- How to Reuse and Repurpose as a Quilter: Tips for Sustainable Sewing

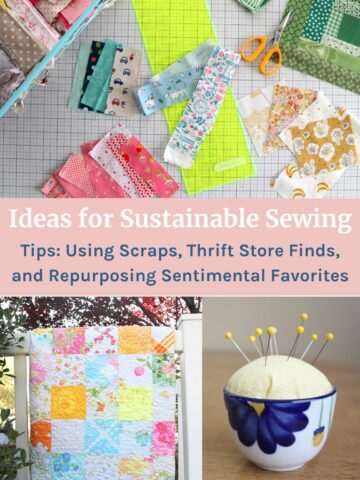

- Projects Made with the Albion Collection

- The Albion Fabric Collection is HERE!

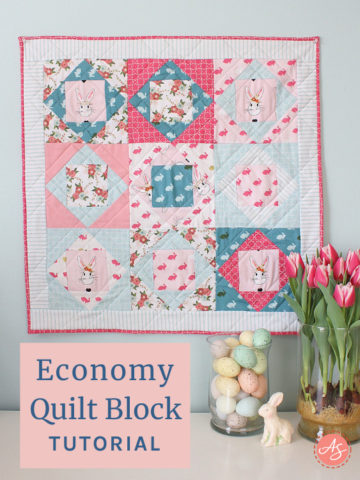

- Economy Quilt Block Tutorial

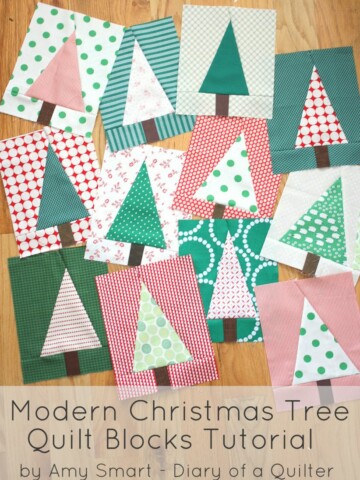

- Journey “Through the Woods” with Sew A Story

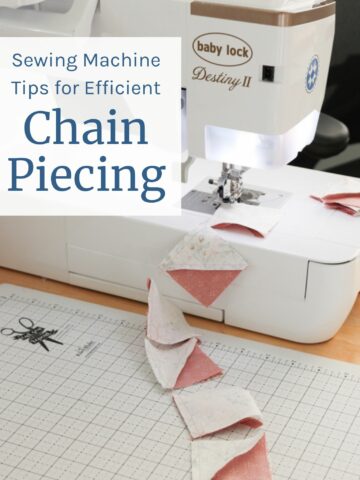

- What is Chain Piecing?

Popular Posts

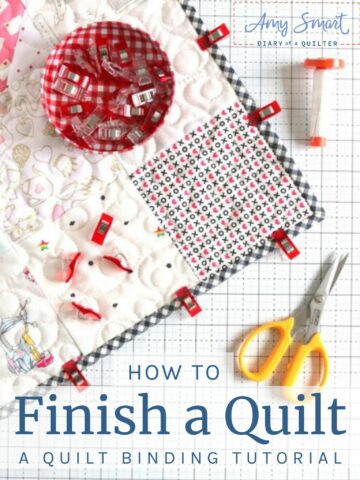

- How to Finish a Quilt

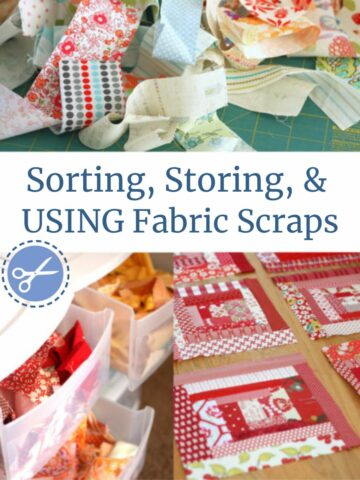

- Sorting, Saving, and Using Fabric Scraps

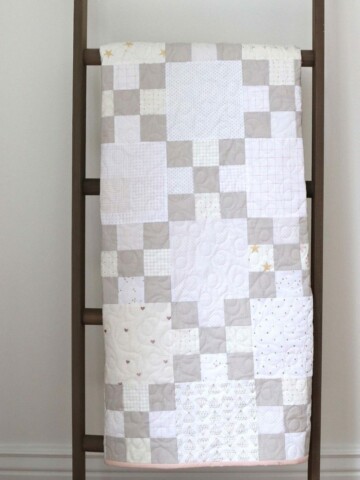

- Top Baby Quilt Tutorials

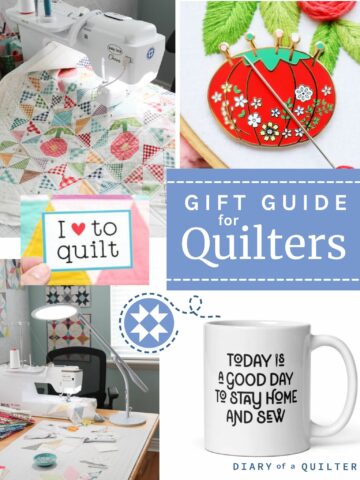

- Gift Guide for Quilters

- How to Make a Patchwork Baby Quilt with Precuts

- Foundation Pieced Log Cabin Quilt Block

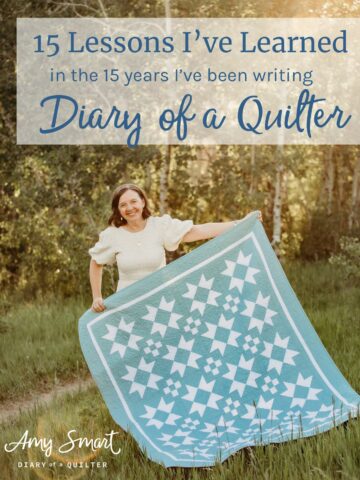

- 15 Lessons I've Learned in 15 Years of Diary of a Quilter

- Life Lessons: When Quilts (and Life) Don't Go According To Plan

Top Quilt Tutorials

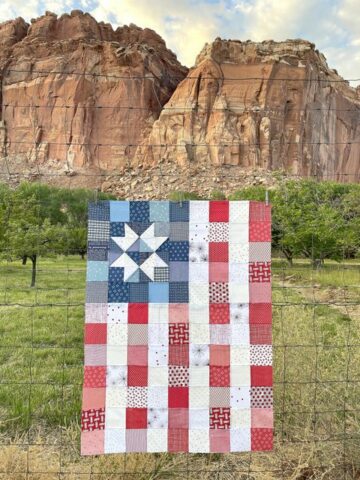

- Sentimental Stars - A Free Quilt Pattern For You

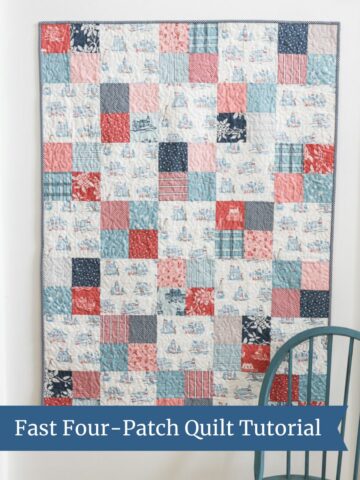

- Fast Four Patch Quilt Tutorial

- Gratitude Quilt - Plus Quilt Tutorial

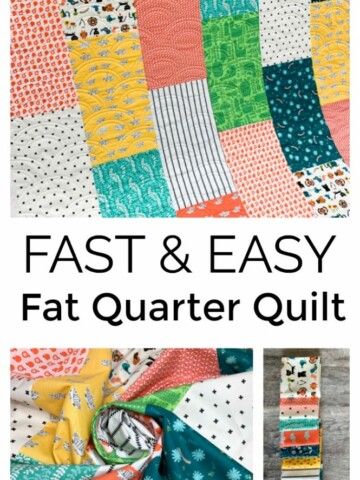

- Fast & Easy Fat Quarter Quilt

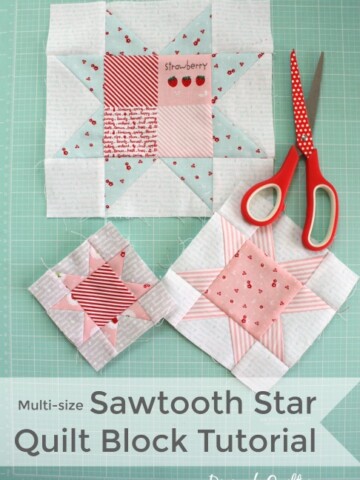

- Fast Flying Geese + Sawtooth Star Quilt Block Tutorial

- How to Make a Manx Quilt Block

- Patchwork Gingham Quilt Pattern and Tutorial

- Star Bright Mini Quilt - Free Pattern